We will delve into the science behind washing machine vibration, the common causes, and the impact it has on the performance of these household appliances.

Contents

- 0.1 The Science Behind Washing Machine Vibration

- 0.2 Common Causes of Washing Machine Vibration

- 0.3 Impact of Vibration on Washing Machine Performance

- 0.4 Why Anti-Vibration Pads Are Essential

- 0.5 Benefits of Using Anti-Vibration Pads

- 0.6 Factors to Consider When Choosing Anti-Vibration Pads

- 1 Types of Anti-Vibration Pads

- 1.1 Type 1. Gel-Based Anti-Vibration Pads

- 1.2 The Best Gel-Based Product: High-Density Gel Anti-Vibration Pads

- 1.3 Type 2. Rubber Anti-Vibration Pads

- 1.4 The Best Rube Product: Heavy-Duty Rubber Anti-Vibration Pads

- 1.5 Type 3. Isolator Anti-Vibration Pads

- 1.6 The Best Isolator Product: Multi-Layer Isolator Anti-Vibration Pads

- 1.7 Type 4. Cork Anti-Vibration Pads

- 1.8 The Best Cork Product: Natural Cork Anti-Vibration Pads

- 1.9 Type 5. Sorbothane’s Anti-Vibration Pads

- 1.10 The Best Sorbothane Product: Market-Leading Sorbothane Anti-vibration Washing Machine Pad from Isolate It

- 1.11 Comparison table of the best anti-vibration pads for washing machines

- 1.12 Conclusion: Best Anti-Vibration Pads for Washing Machines

- 1.13 References

The Science Behind Washing Machine Vibration

Washing machine vibration is a complex phenomenon that involves various scientific principles and mechanical dynamics. One key factor contributing to vibration is the unbalanced load within the drum during the wash cycle. When clothes and water are distributed unevenly, it causes the drum to wobble and vibrate.

Another factor that plays a crucial role in washing machine vibration is the rotational speed of the drum and the centripetal force generated. As the drum spins rapidly, it exerts a force that pushes the water and clothes towards the outer edges, leading to imbalanced forces and resulting in vibration.

Additionally, the structural design and quality of the washing machine can influence vibration. Unstable or poorly constructed machines are more prone to excessive movement and vibration than those with robust and stable designs. Understanding the science behind these factors is vital for diagnosing and resolving issues related to washing machine vibration.

💡Good to know fact: Did you know that excessive vibration can not only damage the washing machine itself but also the surrounding area? It can cause structural damage to the floor, cabinets, and even the walls of your laundry room. That’s why it’s essential to address any vibration issues promptly.

Common Causes of Washing Machine Vibration

There are numerous factors that can contribute to washing machine vibration. Understanding these common causes can help homeowners identify and address the root of the problem. Some of the primary causes include

- Imbalanced load: When clothes or water are unevenly distributed within the drum, it can cause the washer to vibrate excessively.

- Uneven floor: If the washing machine is not placed on a level surface, it can lead to vibration. Even a slight tilt can disrupt the balance and stability of the machine.

- Worn-out or damaged parts: Over time, various components of the washing machine, such as shock absorbers, springs, or suspension rods, can wear out or become damaged, resulting in increased vibration.

- Improper installation: Incorrect installation, such as loose connections or improperly adjusted feet, can cause the washer to vibrate.

To effectively address washing machine vibration, it is crucial to identify and tackle the underlying cause.

Impact of Vibration on Washing Machine Performance

Vibration not only affects the stability and soundness of a washing machine but also directly impacts its performance. Excessive vibration can lead to a range of problems, including

- Reduced cleaning efficiency: When the washing machine vibrates excessively, it hindered the proper movement of clothes and water, leading to suboptimal cleaning results.

- Noise and discomfort: Vibration often generates loud noises, causing inconvenience to homeowners, particularly if the laundry room is adjacent to living areas.

- Increased wear and tear: Continuous vibration can accelerate the wear and tear of various components, leading to costly repairs or premature breakdowns.

Why Anti-Vibration Pads Are Essential

Anti-vibration pads play a crucial role in various industries and applications. They are designed to reduce the transfer of vibrations from one object or structure to another. Whether it’s a heavy machinery or a residential washing machine, vibrations can cause significant damage over time if not properly controlled. These pads are specifically engineered to absorb and dampen vibrations, thus protecting both the equipment and the surrounding structures.

In industries such as manufacturing, construction, and transportation, heavy machinery is often used. The continuous operation of these machines generates substantial amounts of vibrations. These vibrations can result in a range of issues, including noise pollution, structural damage, and even failure of equipment components. By installing anti-vibration pads, these adverse effects can be minimized or eliminated altogether.

Benefits of Using Anti-Vibration Pads

There are several benefits of using anti-vibration pads, making them an essential component in many industries.

1. Vibration Reduction Anti-vibration pads effectively reduce vibrations, preventing excessive wear and tear on machinery and equipment. This can extend the lifespan of critical components and reduce the frequency of repairs and replacements, ultimately saving both time and money.

2. Noise Reduction Vibrations can create excessive noise, leading to discomfort for workers and potential violations of noise regulations. Anti-vibration pads help absorb and dampen vibrations, reducing noise pollution in the workplace or residential environments.

3. Improved Performance: By minimizing vibrations, anti-vibration pads enable machinery and equipment to operate more efficiently and perform optimally. This can result in increased productivity, reduced downtime, and improved overall operational effectiveness.

4. Enhanced Safety: Excessive vibrations can compromise the structural integrity of buildings and machines. By using anti-vibration pads, the risk of structural damage and potential accidents can be significantly reduced, ensuring a safer working environment.

Factors to Consider When Choosing Anti-Vibration Pads

When selecting anti-vibration pads for specific applications, several factors should be taken into consideration to ensure maximum effectiveness

1. Load Capacity: It is important to choose anti-vibration pads that can handle the weight of the equipment or machinery they are intended to support. Pads with insufficient load capacity may compress under heavy loads, compromising their effectiveness.

2. Material Composition: Anti-vibration pads are typically made from various materials such as rubber, neoprene, or cork. Each material has different properties, including durability, flexibility, and resistance to chemicals and oils. The material selection should align with the specific needs of the application.

3. Size and Dimensions: The size and dimensions of the anti-vibration pads must be suitable for the equipment they are designed to support. The pads should provide adequate coverage and support across the entire base of the machinery.

4. Environmental Considerations: Consider the environmental conditions in which the anti-vibration pads will be operating. Factors such as temperature extremes, exposure to chemicals or oils, and outdoor or indoor use can impact the selection of suitable pads for the application.

💡Good to know: Did you know that anti-vibration pads are not only used in industrial settings? They can also be beneficial in residential applications, such as underneath washing machines and HVAC units, to dampen vibrations and reduce noise.

Types of Anti-Vibration Pads

Anti-vibration pads are an essential component in reducing the transmission of vibrations from machinery and equipment to the surrounding environment. These pads are designed to absorb and dissipate vibrations, thereby improving the overall performance and lifespan of the machinery. There are various types of anti-vibration pads available, each with its unique properties and applications. We will explore some of the most common types of anti-vibration pads

Type 1. Gel-Based Anti-Vibration Pads

Gel-based anti-vibration pads are made from a special type of silicone gel that possesses excellent vibration damping properties. These pads are typically used in applications where high levels of vibration isolation are required, such as heavy industrial machinery and precision equipment. The gel material effectively absorbs and dissipates the vibrations, preventing them from being transmitted to the supporting surface.

One of the advantages of gel-based pads is their ability to conform to uneven surfaces, ensuring maximum contact and stability. This makes them particularly useful in instances where the machinery or equipment is placed on an irregular or rough surface. Gel-based pads also offer a high degree of durability and resistance to wear and tear, making them suitable for long-term use.

The Best Gel-Based Product: High-Density Gel Anti-Vibration Pads![]()

The high-density gel anti-vibration pads are designed to absorb and dampen vibrations effectively. These pads are made of durable and flexible materials, allowing them to withstand heavy loads and maintain stability. They feature a non-slip surface that helps to keep the washing machine in place while reducing noise and vibrations.

One of the unique features of these gel pads is their ability to adapt to uneven surfaces. This ensures a secure fit and enhances the overall stability of the washer. Additionally, they are easy to install, making them a popular choice among homeowners and laundry facility operators.

💡Good to know: High-density gel anti-vibration pads can also be used for other appliances such as dryers, refrigerators, and even gym equipment.

Type 2. Rubber Anti-Vibration Pads

Rubber anti-vibration pads are one of the most widely used types of anti-vibration pads due to their versatility and effectiveness. These pads are typically made from high-quality rubber materials that are specifically engineered to absorb and reduce vibrations. Rubber pads are commonly used in a variety of applications, including HVAC systems, generators, compressors, and pumps.

One of the key advantages of rubber anti-vibration pads is their ability to provide both vibration isolation and noise reduction. The rubber acts as a buffer, absorbing the vibrations and preventing them from propagating to the surrounding environment. Additionally, rubber pads have excellent load-bearing capabilities, ensuring stability and preventing excessive movement of the machinery.

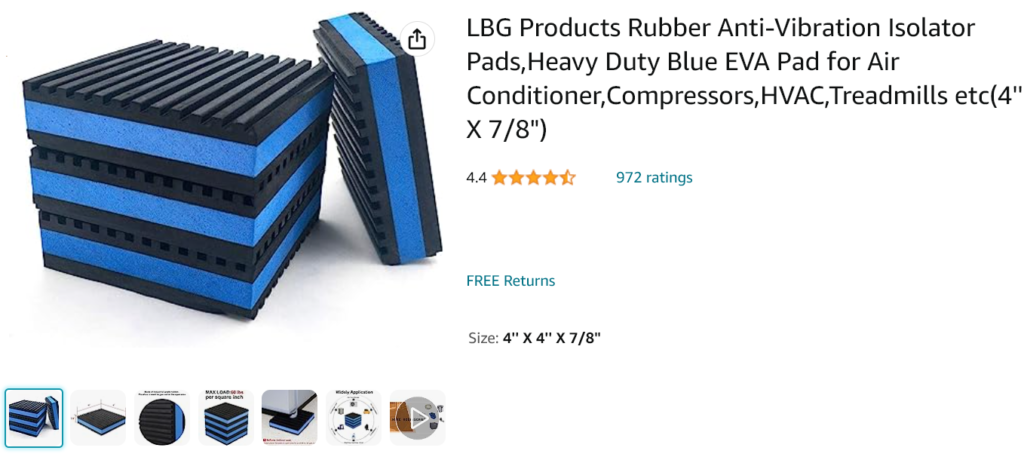

The Best Rube Product: Heavy-Duty Rubber Anti-Vibration Pads

If you’re looking for a durable and long-lasting solution, heavy-duty rubber anti-vibration pads might be the right choice for you. These pads are constructed using high-quality rubber materials with excellent shock absorption capabilities. They effectively reduce vibrations, minimize noise, and prevent the washing machine from shifting or sliding.

Designed to withstand heavy loads and extreme conditions, these rubber pads offer excellent stability and durability. They are resistant to wear and tear, making them ideal for industrial or commercial settings where washing machines are frequently used.

✔️Fun fact: Some heavy-duty rubber anti-vibration gaskets come with built-in adjustable feet, allowing you to adapt the height of your washer according to your needs.

Type 3. Isolator Anti-Vibration Pads

Isolator anti-vibration pads are designed to provide maximum vibration isolation by using a combination of different materials and engineering principles. These pads typically consist of multiple layers, each with different damping properties, stacked together to form a robust isolation system.

Isolator pads are commonly used in heavy-duty industrial applications, such as large motors, pumps, and generators. They are capable of isolating the machinery from low to high-frequency vibrations, ensuring minimal transmission to the surrounding environment. Isolator pads also offer excellent stability and load-bearing capacity, making them suitable for heavy and dynamic loads.

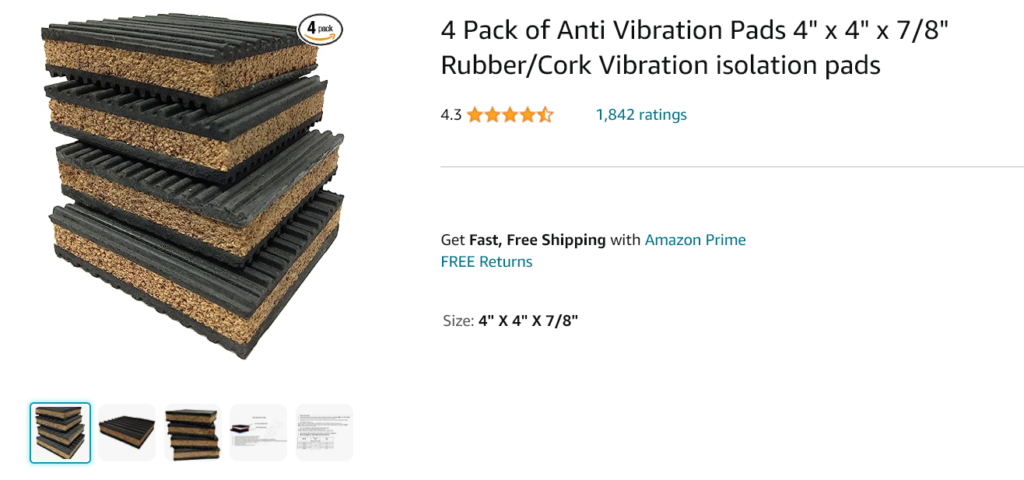

The Best Isolator Product: Multi-Layer Isolator Anti-Vibration Pads

Multi-layer isolator anti-vibration pads are specifically designed to provide maximum damping and vibration isolation. These pads consist of multiple layers of high-quality materials, such as rubber and cork, which work together to absorb and dissipate vibrations effectively.

The unique design of these pads allows them to provide excellent shock absorption while ensuring stability and balance. They are highly versatile and suitable for use with a wide range of washing machine models. Additionally, their compact size makes them easy to install and maintain.

Type 4. Cork Anti-Vibration Pads

Cork anti-vibration pads are made from high-quality natural cork material that possesses excellent damping properties. These pads are commonly used in residential and commercial applications, such as HVAC systems, washing machines, and gym equipment.

One of the advantages of cork anti-vibration pads is their ability to provide superior acoustic insulation, reducing the noise levels generated by the machinery. These pads also offer good compressibility and flexibility, allowing them to conform to uneven surfaces and provide a stable platform for the machinery.

The Best Cork Product: Natural Cork Anti-Vibration Pads

Natural cork anti-vibration pads are an eco-friendly option that provides excellent vibration resistance. These pads are made from renewable cork, which has natural sound-dampening properties. Cork is a sustainable and environmentally friendly material, making it a popular choice among eco-conscious consumers.

Despite their lightweight and slim design, natural cork pads offer impressive shock absorption capabilities. They are resistant to moisture, mold, and mildew, ensuring longevity and performance in any environment. Additionally, cork pads are easy to clean and maintain.

💡Good to Know Fact. Did you know that anti-vibration pads not only reduce noise and vibrations but also help in preventing the premature wear and tear of machinery parts? By absorbing and dissipating vibrations, these pads help in extending the lifespan of the equipment, ultimately saving costs on repairs and replacements.

Type 5. Sorbothane’s Anti-Vibration Pads

Sorbothane, an innovative and unique material known for its superior vibration damping characteristics, has proven itself to be a viable solution for washing machine pads. However, like any material, it carries both advantages and disadvantages that should be carefully considered.

Advantages of Sorbothane Washing Machine Pads

- Exceptional vibration damping: Sorbothane is renowned for its ability to absorb up to 94.7% of vibrations, making it an effective material for reducing noise and minimizing wear and tear in washing machines. [1]

- Resilience: This material exhibits impressive resilience, capable of bouncing back to its original shape after extensive use, thus extending the lifespan of the washing machine pads.

- Temperature resistance: Sorbothane maintains its damping properties in a broad range of temperatures, ensuring the consistency of performance of the washer pads even in various climates.

Disadvantages of Sorbothane Washing Machine Pads

- Cost: Owing to its unique properties and manufacturing process, Sorbothane washing machine pads tend to be more expensive than their counterparts made from more common materials.

- Availability: As a specialized material, Sorbothane may not be as readily available in certain markets, which could limit its accessibility for some consumers.

Good to Know Fact: Sorbothane is also used in various industries beyond household appliances, such as in sports equipment and medical devices, due to its exceptional shock-absorbing properties.

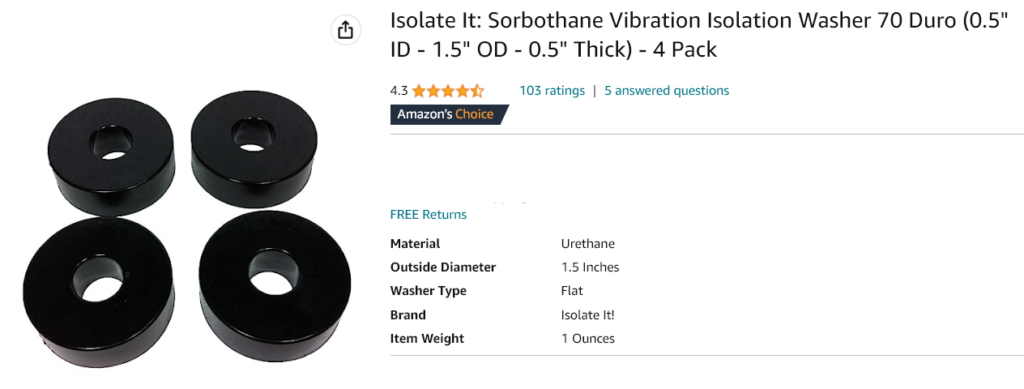

The Best Sorbothane Product: Market-Leading Sorbothane Anti-vibration Washing Machine Pad from Isolate It

The Sorbothane Anti-Vibration System (SAVS) has been consistently well-received by consumers for its robust vibration damping capabilities, quality construction, and easy installation process. As a testament to Sorbothane’s superior performance, the SAVS demonstrates an exemplary application of Sorbothane as a material in reducing both the intensity and the frequency of washing machine vibrations, leading to quieter and smoother operation.

The SAVS, despite its higher price point relative to other anti-vibration pads, has garnered favorable reviews for its longevity and consistency, with many users appreciating the significant reduction in noise and vibration they have experienced with their washers.

Ever wondered how much noise your washing machine produces? It’s estimated that a typical washing machine generates about 70-80 decibels during the spin cycle, equivalent to the noise level of a vacuum cleaner or a busy street. By using Sorbothane anti-vibration pads, you could significantly decrease this noise level, creating a quieter and more peaceful home environment.

Comparison table of the best anti-vibration pads for washing machines

When it comes to washing machines, one common issue many users face is excessive vibrations during the spin cycle. These vibrations can not only be annoying but also lead to potential damage to the machine and surrounding areas.

Next, we will take a closer look at four popular anti-vibration pads for washers.

| Product | Material | Key Features | Pros | Cons |

|---|---|---|---|---|

| High-Density Gel Anti-Vibration Pads | Gel | Flexible, non-slip, adapts to uneven surfaces | Great adaptability, anti-slip property | May degrade faster than others |

| Heavy-Duty Rubber Anti-Vibration Pads | Rubber | Durable, excellent shock absorption | Long lasting, high shock absorption | Less adaptable to uneven surfaces |

| Multi-Layer Isolator Anti-Vibration Pads | Rubber, Cork | Maximum damping, versatile | High damping, versatility | More expensive, may need replacement |

| Natural Cork Anti-Vibration Pads | Cork | Eco-friendly, moisture-resistant | Environmentally friendly, resists moisture | Lower shock absorption capability |

| Sorbothane Material Anti-vibration Pads | Sorbothane | Superior damping, flexibility | Superior absorption, flexibility | Higher cost, may wear out over time |

Choosing the right anti-vibration pads for your washing machine depends on factors such as load capacity, floor type, and personal preference. Consider the material, features, and compatibility to ensure the best fit for your needs. Say goodbye to excessive vibrations and enjoy a quieter laundry experience with these top-quality anti-vibration gaskets!

Conclusion: Best Anti-Vibration Pads for Washing Machines

After exploring the latest trends and innovations in anti-vibration technology, it is clear that the future holds great promise for enhanced vibration dampening. The use of advanced materials, such as nanomaterials and biodegradable materials, along with adaptive and adjustable pad designs, will revolutionize the effectiveness of anti-vibration systems. Additionally, advancements in elastomers and the integration of smart technologies will further enhance vibration reduction capabilities.

When it comes to washing machines, finding the best anti-vibration pad is crucial to minimize noise and reduce potential damage caused by vibrations. Manufacturers are continuously investing in research and development to create cutting-edge anti-vibration pads that provide optimal performance. It is advisable to choose pads that incorporate the latest advancements discussed in this article, such as nanomaterials and adaptive designs, to ensure the best vibration dampening results for your washer.

In conclusion, as technology continues to evolve, anti-vibration technology will play a crucial role in minimizing vibrations and maximizing the performance of various equipment and appliances. The future developments discussed in this article hold the promise of creating safer, quieter, and more efficient environments in a wide range of industries.

💡Good to Know Fact. The first anti-vibration pad was patented in 1904 by Nathaniel Baldwin, an American audio engineer. His design aimed to reduce vibrations produced by early phonographs, resulting in improved sound quality.

| Product | Description | Price |

|---|---|---|

| Gel Anti-Vibration Pad | A revolutionary pad made from carbon nanotubes for exceptional vibration dampening. Suitable for heavy-duty industrial machines. | Check Price |

| Multi Layer Isolator | An adaptive pad with built-in sensors and wireless connectivity for real-time vibration monitoring. Offers remote control and optimization capabilities. | Check Price |

| Cork Vibration Pad | An eco-friendly option made from plant-based biofoams. Provides effective vibration isolation without harming the environment. | Check Price |

References

As an appliance repair company, we take great care in selecting our products based on a combination of our own experience and feedback from our customers. To ensure the reliability and quality of the information we rely on, we turn to trusted sources and official references. Some of the reputable sources we consult include: Official manufacturer information, Trusted industry publications, Recognized consumer advocacy websites 1 2.