Contents

- 0.1 Understanding Refrigerant Leaks

- 0.2 Sources and Causes of Refrigerant Leaks

- 0.3 Signs and Symptoms of Refrigerant Leaks

- 0.4 Types of Refrigerant Leak Detectors

- 0.5 Factors to Consider When Choosing a Refrigerant Leak Detector

- 1 Best Electronic Refrigerant Leak Detectors

- 2 Best Ultrasonic Refrigerant Leak Detectors

- 3 Best UV Dye Refrigerant Leak Detectors

- 4 Tips for Effective Refrigerant Leak Detection

- 4.1 Preparation and Safety Measures

- 4.2 Proper Techniques for Using Refrigerant Leak Detectors

- 4.3 Interpreting and Analyzing Leak Detection Results

- 4.4 The Impact of Refrigerant Leaks on HVAC Systems:

- 4.5 Benefits of Timely Leak Detection and Repair:

- 4.6 Professional Maintenance Strategies for Preventing Leaks:

- 5 Case Studies: Real-Life Experiences

- 5.1 Case Study 1: Detecting and Resolving Refrigerant Leaks in a Commercial Setting

- 5.2 Case Study 2: Residential HVAC System Leak Detection and Repair

- 5.3 Case Study 3: Consequences of Ignoring Refrigerant Leaks

- 5.4 Future Developments in Refrigerant Leak Detection

- 5.5 Best Refrigerant Leak Detectors

- 5.6 Conclusion

Understanding Refrigerant Leaks

Refrigerant is a crucial component of these systems, playing a vital role in the cooling process. When a refrigerant leak occurs, it can lead to a loss of refrigerant, compromising the overall performance of the system. This can result in decreased cooling capacity, inefficient operation, and increased energy consumption.

Moreover, refrigerant leaks have a significant impact on the environment. Many refrigerants used in cooling systems are known to be harmful to the ozone layer and contribute to global warming. The release of these refrigerants into the atmosphere can exacerbate climate change and harm the environment. Therefore, early detection and repair of refrigerant leaks are crucial for minimizing the environmental impact and ensuring sustainable cooling practices.

Failing to detect and address refrigerant leaks can also pose risks to human health. Certain refrigerants, such as chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), can displace oxygen in confined spaces, leading to asphyxiation. Additionally, some refrigerants can cause respiratory issues and skin irritations if exposed to for prolonged periods.

To effectively detect refrigerant leaks, various methods and technologies are used. These include visual inspections, electronic leak detectors, ultrasonic leak detectors, and sniffers. Regular maintenance and monitoring of refrigeration systems are essential to identify and rectify leaks promptly, thereby ensuring the safety and efficiency of the system.

Sources and Causes of Refrigerant Leaks

Refrigerant leaks can originate from several sources within refrigeration systems. The most common causes of refrigerant leaks include:

- Wear and tear: Over time, the components of a refrigeration system can deteriorate, leading to leaks.

- Physical damage: Accidental damage to refrigerant lines or coils can result in refrigerant leaks.

- Poor installation or maintenance: Improper installation or inadequate maintenance practices can contribute to refrigerant leaks.

- Manufacturing defects: Defects in the manufacturing process of refrigeration equipment can cause leaks.

It is essential to identify the sources and causes of refrigerant leaks to implement preventive measures effectively. By addressing these underlying issues and improving maintenance practices, the likelihood of future leaks can be minimized.

Signs and Symptoms of Refrigerant Leaks

Refrigerant leaks can manifest through various signs and symptoms. The most common indicators of refrigerant leaks include:

- Inadequate cooling: If a refrigeration system is no longer able to maintain the desired temperature, it may be a sign of a refrigerant leak.

- Icing or frost formation: Excessive ice or frost on the evaporator coil can indicate a refrigerant leak.

- Noisy operation: Unusual noises coming from the refrigeration system may be a result of a refrigerant leak.

- Increased energy consumption: A sudden spike in energy consumption could be indicative of a refrigerant leak.

- Presence of oil stains: Oil stains or residues around the refrigeration system can suggest a leak.

Good to know: Refrigerant leaks not only affect traditional cooling systems but also have implications for other industries that rely on refrigeration, such as food and beverage processing, pharmaceuticals, and HVAC systems. Understanding and addressing refrigerant leaks are vital for ensuring the smooth operation of these industries.

Recognizing these signs and symptoms can help identify refrigerant leaks early on, allowing for prompt repairs and maintenance to mitigate further damage and prevent potential hazards.

Did you know? The global production and consumption of hydrofluorocarbons (HFCs), commonly used as refrigerants, are projected to increase in the coming years, highlighting the urgency of effective leak detection and prevention in refrigeration systems.

Types of Refrigerant Leak Detectors

By detecting and repairing leaks, these detectors ensure the efficient operation of refrigeration systems, prevent refrigerant loss, and minimize environmental impacts.

There are several types of refrigerant leak detectors available in the market, and this article will discuss three of the most commonly used ones: electronic refrigerant leak detectors, ultrasonic refrigerant leak detectors, and UV dye refrigerant leak detectors.

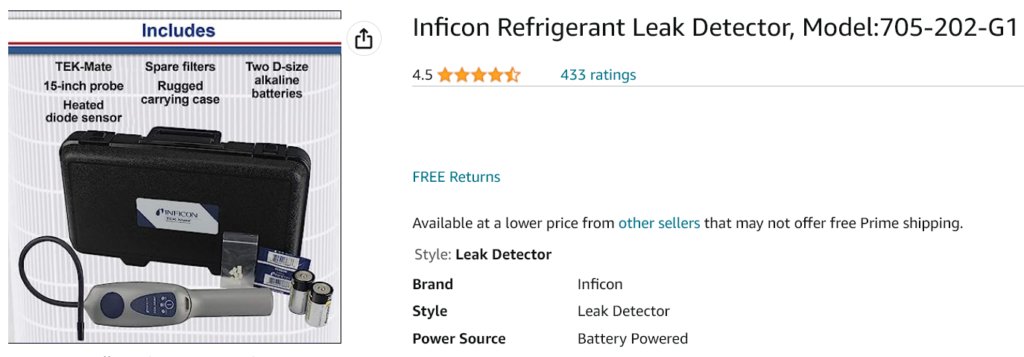

Electronic Refrigerant Leak Detectors

Electronic refrigerant leak detectors are widely used in the HVACR industry due to their high sensitivity and reliability. These detectors utilize advanced sensor technology to detect the presence of refrigerant gases in the air. When a refrigerant leak is detected, the detector emits an audible or visual alarm, alerting the user. Some electronic detectors also come with a digital display that shows the concentration of the detected gas, allowing for easier leak identification.

- Handheld Electronic Leak Detectors: These detectors are portable devices that can be easily carried around by technicians. They are battery-operated and have a flexible probe, which allows for convenient leak detection in hard-to-reach areas.

- Fixed Electronic Leak Detectors: Fixed electronic leak detectors are permanently installed in refrigeration systems and continuously monitor the environment for the presence of refrigerant leaks. These detectors are commonly used in commercial and industrial settings where constant monitoring is required.

Ultrasonic Refrigerant Leak Detectors

Ultrasonic refrigerant leak detectors are innovative devices that use ultrasonic sound waves to locate refrigerant leaks. These detectors work by translating the ultrasonic sound emissions generated by a leak into audible sounds that can be heard by the user. Ultrasonic detectors are extremely useful in detecting leaks in areas that are difficult to access visually.

- Handheld Ultrasonic Leak Detectors: Handheld ultrasonic leak detectors are easy-to-use devices that allow technicians to quickly locate refrigerant leaks by listening for the distinct sound frequencies produced by the escaping gas.

- Ultrasonic Inspection Systems: Ultrasonic inspection systems are sophisticated setups that use multiple sensors and advanced signal processing techniques to accurately locate and evaluate refrigerant leaks in large refrigeration systems. These systems are commonly used in industrial applications where a high level of precision is required.

UV Dye Refrigerant Leak Detectors

UV dye refrigerant leak detectors are unique tools that use fluorescent dye to identify refrigerant leaks. These detectors work by injecting UV dye into the refrigeration system, which circulates with the refrigerant. When a leak occurs, the dye escapes and becomes visible under UV light. UV dye detectors are particularly useful in pinpointing hard-to-find leaks.

- UV Dye Kits: UV dye kits typically include a UV light and dye injector. The UV light is used to illuminate the dye and make it visible, while the injector ensures the dye is properly introduced into the system. These kits are commonly used by technicians to identify leaks in automotive air conditioning systems.

- UV Dye Additives: UV dye additives are designed to be added directly to the refrigerant during maintenance or service. The dye circulates with the refrigerant and can aid in identifying leaks when using a UV light.

Each type of refrigerant leak detector has its own advantages and applications. The choice of detector depends on various factors, such as the type of refrigerant used, the size of the system, the location of potential leaks, and the specific requirements of the job at hand.

Good to know: The use of refrigerant leak detectors is essential for both residential and commercial HVACR systems. Proper leak detection and repair not only ensure the efficient operation of the system but also contribute to reducing greenhouse gas emissions and protecting the environment.

Factors to Consider When Choosing a Refrigerant Leak Detector

Sensitivity and Detection Range

When selecting a refrigerant leak detector, sensitivity and detection range are vital factors to consider. The sensitivity determines how well the detector can detect even the smallest leaks, while the detection range refers to the maximum distance at which the detector can identify a leak.

Typically, refrigerant leak detectors come with different sensitivity levels, ranging from high to low. A higher sensitivity level ensures that no leak goes undetected, providing accurate and dependable results. This is especially crucial in sensitive environments such as laboratories, hospitals, and food storage facilities.

Furthermore, the detection range is a crucial consideration, as it determines the efficiency of the detector in large and open spaces. Advanced leak detectors can cover larger areas, making them ideal for commercial buildings or industrial facilities.

Response Time and Accuracy

The response time and accuracy of a refrigerant leak detector are essential for timely and precise detection of leaks. The response time refers to how quickly the detector detects a leak once it is present, minimizing the risk of potential health hazards or environmental damage.

A fast response time is invaluable, especially in critical situations where immediate action is necessary. Additionally, accuracy is crucial to ensure reliable and consistent leak detection results. An accurate detector guarantees that false positives or negatives are minimized, allowing users to quickly identify the source of the leak and make appropriate repairs.

Portability and Ease of Use

Portability and ease of use are important factors to consider when choosing a refrigerant leak detector. Portability enables users to move the detector around easily and inspect different areas without restriction. It is particularly beneficial for technicians who need to navigate through complex systems or work in various locations.

Additionally, ease of use is crucial for efficient and effective leak detection. A user-friendly interface, clear visual indicators, and audible alarms enhance the detector’s usability, minimizing the need for extensive training or expertise.

Good to know! Did you know that refrigerant leak detectors can be used not only in HVAC systems but also in automotive air conditioning units? These detectors help prevent refrigerant leaks in cars, ensuring optimal performance and reducing environmental impact.

Best Electronic Refrigerant Leak Detectors

Product 1: Advanced Electronic Leak Detector with Infrared Sensor

If you’re looking for a leak detector that combines cutting-edge technology with user-friendly features, the Advanced Electronic Leak Detector with Infrared Sensor is an excellent choice. This innovative device utilizes infrared technology to detect the presence of refrigerant leaks accurately.

Equipped with an advanced filtration system, this detector can distinguish between refrigerant gases and other airborne substances, ensuring precise leak detection. Its infrared sensor provides unparalleled sensitivity and can detect leaks even in the most challenging environments.

The compact design and ergonomic grip make it easy to handle and maneuver, allowing you to access tight spaces with ease. Additionally, the intuitive interface and adjustable sensitivity settings ensure a hassle-free operation. You can rely on this leak detector to provide accurate results and save valuable time during your diagnostic process.

Product 2: Compact and Versatile Refrigerant Leak Detector

If you prefer a leak detector that offers both portability and versatility, the Compact and Versatile Refrigerant Leak Detector is an excellent option. This compact device packs a punch and is designed to detect leaks in various refrigeration systems, including HVAC units, automobiles, and industrial applications.

With its advanced microprocessor technology, this leak detector provides reliable and precise results. The audible and visual indicators help you quickly identify the presence of leaks, while the adjustable sensitivity allows you to fine-tune the detection level based on your specific needs.

Thanks to its ergonomic design and lightweight construction, this leak detector can be easily carried around, making it ideal for on-the-go professionals. Whether you’re working in confined spaces or larger areas, this detector will aid you in detecting refrigerant leaks efficiently and effectively.

Product 3: Professional-Grade Portable Leak Detector with Adjustable Sensitivity

For those seeking a professional-grade leak detector that offers exceptional performance and durability, the Professional-Grade Portable Leak Detector with Adjustable Sensitivity is a standout choice. This rugged device is designed to withstand the demands of industrial environments while delivering unmatched accuracy in leak detection.

Equipped with advanced sensors and a powerful pump system, this leak detector can quickly locate refrigerant leaks of any size. The adjustable sensitivity allows you to set the detection level precisely, ensuring optimal results without any false alarms.

Featuring a large LCD display and user-friendly controls, this detector offers a seamless user experience. The ergonomic handle and robust construction make it suitable for heavy-duty use, and the rechargeable battery ensures extended operation time.

Good to Know. Did you know that refrigerant leaks can lead to reduced cooling performance, increased energy consumption, and potential damage to the compressor? Regular inspections and using high-quality leak detectors can help prevent these issues and save you time and money in the long run.

Best Ultrasonic Refrigerant Leak Detectors

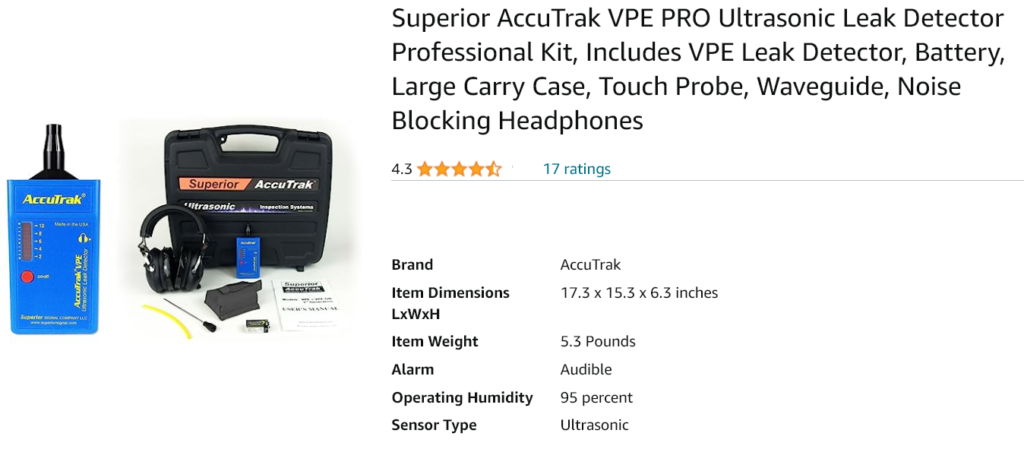

Product 1: AccuTrak Ultrasonic Leak Detector with Advanced Noise Filtering

Our first featured product is the Ultrasonic Leak Detector with Advanced Noise Filtering. This innovative device utilizes cutting-edge technology that allows it to filter out background noise and focus on the unique sound signatures produced by refrigerant leaks. With its exceptional sensitivity, you can easily identify and pinpoint even the smallest of leaks, saving you time and effort in the diagnostic process.

This leak detector comes equipped with a high-quality probe that allows for precise detection in hard-to-reach areas, ensuring comprehensive leak detection. Its intuitive interface and user-friendly controls make it suitable for both experienced technicians and DIY enthusiasts looking to tackle refrigerant leaks on their own.

Key features of the Ultrasonic Leak Detector with Advanced Noise Filtering include:

- Advanced noise filtering technology for accurate detection.

- High sensitivity to detect even minor leaks.

- Ergonomic design with a comfortable grip for extended use.

- LED display for easy visual indication of leaks.

With its advanced features and reliable performance, the Ultrasonic Leak Detector with Advanced Noise Filtering is an indispensable tool for anyone involved in refrigerant leak detection.

Product 2: High-Precision Ultrasonic Leak Detector with Visual and Audible Indicators

Our next featured product is the High-Precision Ultrasonic Leak Detector with Visual and Audible Indicators. This state-of-the-art device combines accuracy with convenience to provide an effective solution for detecting refrigerant leaks. Its dual-mode functionality allows you to choose between visual and audible leak detection indicators, depending on your preference and environment.

The High-Precision Ultrasonic Leak Detector is designed to quickly and accurately locate leaks in various appliances, such as refrigerators, air conditioners, and heat pumps. Its compact size and lightweight construction make it easy to carry and handle during inspections.

Key features of the High-Precision Ultrasonic Leak Detector with Visual and Audible Indicators include:

- Accurate and reliable detection of refrigerant leaks.

- Dual-mode functionality for visual and audible indications.

- Adjustable sensitivity settings for personalized leak detection.

- Ergonomic design for comfortable and prolonged use.

With its high precision and multiple detection options, the High-Precision Ultrasonic Leak Detector is a must-have tool for professionals seeking efficient and dependable refrigerant leak detection.

Product 3: Dual-Mode Ultrasonic Leak Detector for Fast and Accurate Leak Detection

Our final featured product is the Dual-Mode Ultrasonic Leak Detector for Fast and Accurate Leak Detection. This versatile device offers two modes of operation: the ultrasonic mode for detecting refrigerant leaks and the stethoscope mode for identifying mechanical problems in appliances.

The Dual-Mode Ultrasonic Leak Detector is engineered to deliver fast and accurate results, enabling technicians to quickly diagnose and fix any refrigerant-related issues. Its intuitive interface and easy-to-read display make it simple to navigate through the various settings and modes.

Key features of the Dual-Mode Ultrasonic Leak Detector for Fast and Accurate Leak Detection include:

- Dual-mode functionality for refrigerant leak detection and mechanical issue diagnosis.

- Digital display for clear and precise readings.

- Adjustable volume and sensitivity settings for enhanced detection.

- High-quality headphones for improved audio output.

With its dual capabilities and user-friendly design, the Dual-Mode Ultrasonic Leak Detector is a valuable asset for technicians looking for a versatile and efficient tool to detect and diagnose refrigerant leaks.

Good to Know. It is important to regularly inspect and maintain your appliances to ensure they are functioning optimally. By using an ultrasonic refrigerant leak detector, you can identify leaks early on and prevent potential damage to your appliances and the environment.

Best UV Dye Refrigerant Leak Detectors

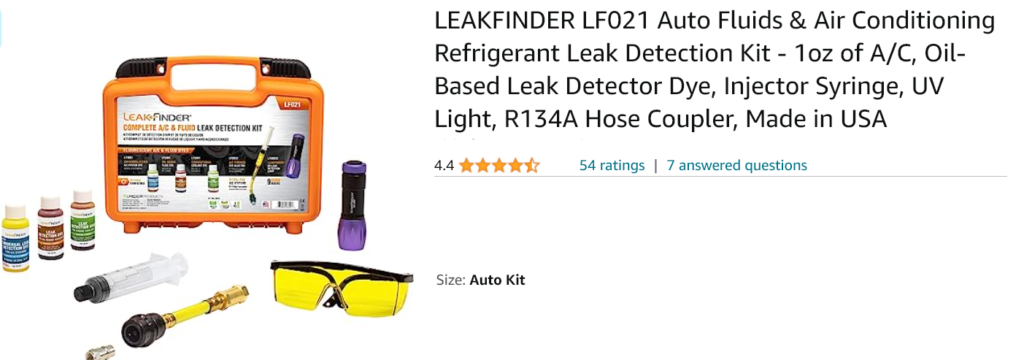

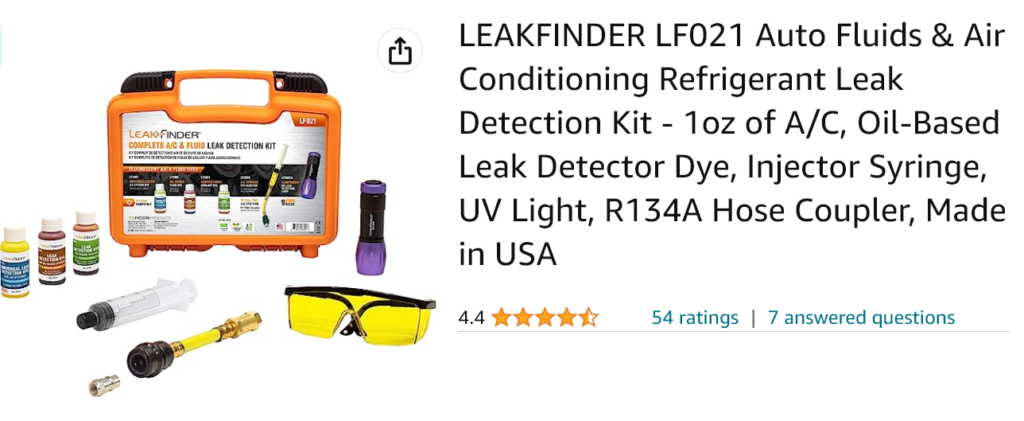

Product 1: UV Dye Leak Detection Kit with UV Light and Glasses

The Leakfinder UV Dye Leak Detection Kit with UV Light and Glasses is an indispensable tool for detecting refrigerant leaks in HVAC systems, automotive air conditioning systems, and industrial equipment. This comprehensive kit includes a UV dye, a UV light, and special glasses to help locate and pinpoint leaks quickly and efficiently.

The UV dye, also known as a fluorescent dye, is added to the refrigerant system. When the dye escapes through a leakage point, it interacts with the UV light, causing it to fluoresce and become highly visible. The UV light enables technicians to identify leaks even in hard-to-reach areas.

The included glasses are designed to enhance visibility of the fluorescent dye, making it easier for technicians to see the leaks. The glasses filter out unnecessary light and allow the dye to stand out, enhancing the detection process.

- Easy-to-use: The kit is designed to be user-friendly, allowing both professional technicians and DIY enthusiasts to detect leaks easily.

- Accurate results: The combination of the UV dye, UV light, and glasses ensures accurate and reliable leak detection.

- Versatile: The kit can be used in various applications, including HVAC systems, automotive air conditioning systems, and industrial equipment.

- Durable: The components of the kit are made of high-quality materials, ensuring long-lasting performance.

With the UV Dye Leak Detection Kit with UV Light and Glasses, technicians can quickly and effectively identify refrigerant leaks, saving time and money on repairs and maintenance.

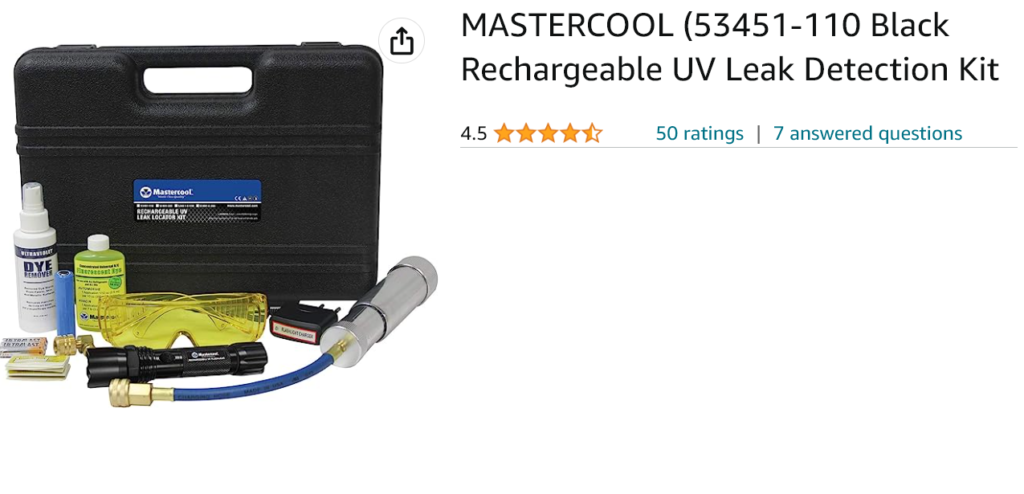

Product 2: Professional UV Dye Refrigerant Leak Detector

The Professional UV Dye Refrigerant Leak Detector is a powerful and reliable tool designed specifically for detecting refrigerant leaks in various systems. This device is widely used in the HVAC industry, automotive repair shops, and other maintenance and repair applications.

The detector works by sensing the presence of UV dye, which is added to the refrigerant system. As the dye leaks out of the system, the detector alerts the user by emitting an audible and visible alarm. This allows technicians to accurately locate and repair the leaks efficiently.

- High sensitivity: The Professional UV Dye Refrigerant Leak Detector can detect even the smallest leaks, ensuring no leakage goes unnoticed.

- Quick response: The detector provides instant feedback, allowing technicians to identify and address leaks promptly.

- Ergonomic design: The device is designed to be comfortable to hold and easy to operate, minimizing user fatigue during extended use.

- Durable construction: The detector is built to withstand demanding working environments, ensuring long-term reliability.

With its advanced features and reliable performance, the Professional UV Dye Refrigerant Leak Detector is a top choice for professionals in the industry.

Product 3: UV Dye Leak Detection Pen for Quick and Easy Detection

The UV Dye Leak Detection Pen is a portable and convenient tool that offers quick and easy detection of refrigerant leaks. This pen-shaped device is specifically designed for on-the-go technicians who need a compact solution for detecting leaks in HVAC systems, automotive air conditioning systems, and other applications.

The pen contains a UV dye that is applied directly onto suspected areas. The dye will interact with the UV light, making any leaks visible to the user. The pen also features a built-in UV light for easy detection, eliminating the need for additional equipment.

- Compact and portable: The pen’s compact size allows for easy storage and transportation, making it ideal for technicians who are always on the move.

- User-friendly: The pen is designed for simple operation, requiring no technical expertise to use effectively.

- Cost-effective: The UV Dye Leak Detection Pen offers an affordable solution for leak detection without compromising on accuracy.

Technicians can rely on the UV Dye Leak Detection Pen for quick and efficient leak detection in various applications, ensuring efficient troubleshooting and maintenance.

Good to know. UV dye refrigerant leak detectors are widely used in the industry due to their effectiveness in locating leaks. However, it is important to follow safety guidelines and manufacturer instructions when handling UV dyes and using UV light sources.

Tips for Effective Refrigerant Leak Detection

Preparation and Safety Measures

Before initiating the refrigerant leak detection process, it is crucial to take certain preparation steps and follow safety measures to prevent any potential hazards and ensure efficient leak detection.

- Turn off the Power: Always turn off the power supply to the system that is being tested. This will protect you from electric shock and prevent any damage to the equipment. Safety should always be a top priority.

- Wear Appropriate Safety Gear: To protect yourself from harmful chemicals and contaminants, wear personal protective equipment (PPE) such as safety goggles, gloves, and a respirator. This will minimize the risk of exposure to toxic substances during the leak detection process.

- Clear the Area: Make sure the area around the refrigeration system is clear of any obstacles or potential hazards. This will allow you to work efficiently and reduce the risk of accidents while conducting the leak detection process.

- Check for Ventilation: Ensure that the area you are working in is well-ventilated. Proper ventilation helps in dissipating any leaked refrigerant, preventing the accumulation of harmful gases in the surrounding environment.

- Identify Potential Leak Points: Familiarize yourself with common areas where refrigerant leaks are likely to occur. These can include valves, fittings, joints, rubber hoses, and connections. Prioritize these areas during the leak detection process for a more targeted approach.

Proper Techniques for Using Refrigerant Leak Detectors

Now that you have prepared the environment and taken necessary safety precautions, it’s time to focus on the proper techniques for using refrigerant leak detectors. These detectors play a crucial role in identifying even the smallest leaks, ensuring efficient detection and minimizing refrigerant loss.

- Select the Right Detector: There are various types of leak detectors available, including electronic, ultrasonic, and bubble solutions. Choose the detector that best suits your application and offers the highest sensitivity and accuracy for your specific refrigerant.

- Start with a Clean System: Before using a leak detector, make sure the system is clean from any debris, oil, or dirt that may interfere with the accuracy of the readings. Clean the system thoroughly to ensure reliable results.

- Calibrate the Detector: Regularly calibrate the leak detector according to the manufacturer’s instructions to maintain its accuracy. Calibration helps in providing precise measurements and reduces the occurrence of false readings.

- Move Slowly and Methodically: When using the leak detector, move slowly and methodically around the potential leak points. Pay close attention to any changes in the detector’s readings or any audible warnings indicating a possible leak.

- Take Multiple Readings: To ensure accurate results, take multiple readings at different locations near the suspected leak points. This will help you confirm the presence of a leak and determine its severity.

Interpreting and Analyzing Leak Detection Results

Once you have conducted the leak detection process, the next step is to interpret and analyze the results. This information will guide you in taking appropriate action to repair the leak and restore the system’s integrity.

- Document the Findings: Keep a detailed record of the leak detection results, including the location, severity, and any relevant observations. This documentation will assist you in tracking the history of leaks and identifying potential recurring issues.

- Assess the Severity: Determine the severity of the detected leak based on the leak detector’s readings and manufacturer guidelines. Some detectors provide numerical values or audible alerts to help you identify the leak’s seriousness.

- Consult Manufacturer Guidelines: Refer to the system or equipment manufacturer’s guidelines to understand the acceptable leak rate for your specific application. This will provide valuable information on whether immediate action is required or if the leak can be addressed during regular maintenance.

- Repair the Leak: Once you have evaluated the leak severity and consulted the manufacturer’s guidelines, take appropriate measures to repair the leak. This may involve replacing defective parts, tightening connections, or applying sealants as recommended.

- Recheck the System: After repairing the leak, recheck the system using the leak detector to ensure successful repair and leak elimination. This step is crucial to confirm that the repair process was effective and the system is now leak-free.

We hope these tips for effective refrigerant leak detection prove helpful in your endeavors. By following proper techniques and safety measures, you can efficiently detect refrigerant leaks, maintain system integrity, and promote environmental sustainability.

Good to know! Did you know that refrigerant leaks not only impact the environment but can also lead to reduced system performance, increased energy consumption, and higher repair costs? Detecting and repairing leaks promptly is essential to avoid these issues.

Keep in mind that regular maintenance and inspections play a vital role in preventing refrigerant leaks. By implementing effective leak detection strategies, you can save money, protect the environment, and ensure optimal performance of your refrigeration systems.

The Impact of Refrigerant Leaks on HVAC Systems:

Refrigerant leaks can have a significant impact on the performance and efficiency of HVAC (Heating, Ventilation, and Air Conditioning) systems. Refrigerants are the lifeblood of these systems, as their primary function is to absorb and release heat in order to regulate the temperature and maintain a comfortable environment. When a leak occurs, the refrigerant levels in the system decrease, resulting in numerous detrimental effects.

Benefits of Timely Leak Detection and Repair:

Timely detection and repair of refrigerant leaks in HVAC systems offer several benefits that extend beyond mere performance improvements.

| Impact of Refrigerant Leaks | Description |

|---|---|

| Reduced Cooling Capacity | A decrease in refrigerant levels leads to diminished heat removal efficiency. This causes the HVAC system to underperform, creating an uncomfortably warm indoor environment. |

| Poor Air Quality | Leaks can allow contaminants such as dust, dirt, and pollen to enter the system and circulate throughout the building. This can potentially affect the health of occupants, particularly those with respiratory conditions or allergies. |

| Increased Energy Consumption | As the cooling capacity drops, the HVAC system has to work harder to maintain the desired temperature, leading to increased energy usage. This not only results in higher utility bills but also causes additional wear and tear on system components, which can escalate maintenance and repair costs. |

| Environmental Impact | HVAC systems often use refrigerants like hydrochlorofluorocarbons (HCFCs) and chlorofluorocarbons (CFCs) that contribute to ozone depletion and climate change. Leaks release these harmful substances into the atmosphere, worsening these environmental issues. Regular maintenance and repair can help prevent and address such leaks, thereby minimizing their environmental impact. |

Professional Maintenance Strategies for Preventing Leaks:

Regular maintenance is crucial for preventing refrigerant leaks in HVAC systems. Here are some professional strategies that can help maintain the integrity of the system:

- System Inspections: Routine inspections by trained professionals can help identify potential leaks or areas of concern in the HVAC system. These inspections may include checking connections, valves, and fittings for signs of leakage or wear.

- Refrigerant Pressure Tests: Periodic pressure tests can detect leaks before they become larger issues. These tests involve pressurizing the system with nitrogen or another inert gas to identify any substantial drops in pressure that may signify a leak.

- Proper Installation: Ensuring HVAC systems are installed correctly by experienced professionals helps minimize the risk of future leaks. Proper installation includes adequate sealing of connections and meticulous attention to detail during the setup process.

- Regular Maintenance Schedule: Establishing a regular maintenance schedule, including filter changes, coil cleanings, and refrigerant checks, is essential for maintaining optimal system performance and preventing leaks. This schedule should be adhered to diligently to ensure the longevity of the HVAC system.

Good to Know. Did you know that refrigerant leaks not only impact residential and commercial HVAC systems, but they can also affect automotive air conditioning systems? Regular maintenance and prompt leak detection are just as important for vehicles to ensure efficient and safe operation.

Case Studies: Real-Life Experiences

Case Study 1: Detecting and Resolving Refrigerant Leaks in a Commercial Setting

In this case study, we examine how a professional HVAC technician tackled the challenge of detecting and resolving refrigerant leaks in a large commercial building. The technician employed advanced leak detection techniques, such as ultrasonic and infrared leak detection, to pinpoint the exact location of the leaks.

Key Findings:

- The leaks were primarily found in the condenser coils and valves of the HVAC system.

- The technician utilized a refrigerant leak detector to identify the leaks accurately.

- Once the leaks were detected, the technician promptly repaired and sealed them to prevent further loss of refrigerant.

This case study highlights the importance of regular maintenance and leak detection in commercial settings to ensure optimal performance and energy efficiency of HVAC systems. Implementing preventive measures can save businesses significant costs in the long run.

Case Study 2: Residential HVAC System Leak Detection and Repair

In this case study, we focus on the experience of a homeowner who encountered issues with their residential HVAC system due to refrigerant leaks. The homeowner noticed a decrease in cooling efficiency and decided to call in a professional technician to address the problem.

Key Findings:

- The technician conducted a thorough inspection of the HVAC system to identify any potential leaks.

- Using a refrigerant leak detection kit, the technician successfully located multiple leaks in the evaporator coil of the air conditioning unit.

- The leaks were repaired, and the system was recharged with the appropriate amount of refrigerant.

Through this case study, we understand the importance of prompt action when it comes to resolving refrigerant leaks in residential settings. Ignoring leaks not only leads to increased energy consumption but also compromises the overall comfort and performance of the HVAC system.

Case Study 3: Consequences of Ignoring Refrigerant Leaks

In this intriguing case study, we examine the repercussions of ignoring refrigerant leaks in a commercial setting over an extended period. The company in question neglected to address ongoing refrigerant leaks in their HVAC system, unaware of the potential consequences.

Key Findings:

- As the leaks went unnoticed and unaddressed, the company experienced a significant increase in energy bills.

- The lack of maintenance also resulted in decreased cooling capacity and compromised indoor air quality.

- Eventually, major components of the HVAC system failed, requiring costly repairs and replacement.

This eye-opening case study highlights the importance of regular maintenance and timely leak detection. By addressing refrigerant leaks promptly, businesses can avoid unnecessary expenses and ensure optimal efficiency and performance of their HVAC systems.

Good to Know: Did you know that a single leaking valve can contribute to an average refrigerant loss of 1,000 pounds per year? That’s equivalent to 483,000 liters of wasted refrigerant!

Explore these real-life case studies to gain valuable insights into the detection and resolution of refrigerant leaks in commercial and residential settings. Remember, it’s always better to be proactive in maintaining your HVAC system to avoid costly repairs and unnecessary energy expenses.

Future Developments in Refrigerant Leak Detection

In recent years, there have been significant advancements in refrigerant leak detection technology. These advancements are driven by the increasing demand for efficient and sustainable refrigeration systems. Leakage of refrigerants not only contributes to global warming but also poses risks to human health. Therefore, it is crucial to develop innovative and reliable methods for detecting leaks in refrigeration systems.

Advancements in Leak Detection Technology

One of the key areas of advancement in refrigerant leak detection technology is the development of highly sensitive and accurate sensors. Traditional methods of leak detection, such as bubble testing or electronic detectors, are often limited in their ability to detect small leaks or specific refrigerant types. However, with the introduction of advanced sensor technologies, such as laser-based spectroscopy and infrared imaging, it is now possible to detect even the tiniest leaks with high precision.

These sensors utilize different detection principles, such as the absorption of specific wavelengths of light by refrigerant molecules or the measurement of temperature gradients caused by refrigerant leaks. They can be integrated into refrigeration systems or deployed as standalone devices to constantly monitor the presence of refrigerants in the surrounding environment.

Furthermore, emerging technologies such as nanomaterial-based sensors and wearable devices show great potential for enhancing leak detection capabilities. Nanomaterials, with their unique properties at the nanoscale, enable highly sensitive and selective detection of refrigerants. Wearable devices, on the other hand, allow for continuous monitoring of refrigeration systems, providing real-time data on potential leakages.

Emerging Trends in Sustainable Refrigerant Leak Detection

With the increasing focus on sustainability, there is a growing demand for environmentally friendly leak detection methods. Traditional refrigerant leak detection methods often involve the use of chemical-based substances, such as soapy water or leak detection sprays, which can be harmful to the environment.

To address this issue, researchers are exploring alternative methods that do not rely on chemical substances. For example, some studies have investigated the use of natural gas tracers, such as methane or ethane, as indicators of refrigerant leaks. These natural gas tracers are non-toxic and have low environmental impact, making them a more sustainable option.

Additionally, the integration of machine learning and artificial intelligence (AI) algorithms into leak detection systems shows promise in improving sustainability. By analyzing large amounts of data collected from refrigeration systems, these algorithms can identify patterns and anomalies that indicate potential leaks. This not only improves the accuracy of leak detection but also enables predictive maintenance, reducing the likelihood of leaks and minimizing environmental impact.

Potential Integration of IoT and Smart Technologies

As technology continues to evolve, the future of refrigerant leak detection lies in the integration of Internet of Things (IoT) devices and smart technologies. IoT devices, such as wireless sensors and cloud-based monitoring systems, can provide real-time data on refrigerant levels, temperatures, and other relevant parameters.

By connecting these devices to a centralized monitoring system, facility managers can easily track the performance of multiple refrigeration systems and detect leaks in real time. This allows for proactive maintenance, minimizing downtime and reducing the risk of costly repairs.

Furthermore, the combination of IoT devices with smart technologies, such as machine learning and data analytics, opens up new possibilities for optimizing refrigeration system performance. These technologies can identify inefficiencies, predict potential failures, and recommend corrective actions, ultimately leading to more energy-efficient and reliable refrigeration systems.

Best Refrigerant Leak Detectors

| Product | Features |

|---|---|

| Type A |

|

| Type B |

|

| Type C |

|

Good to know. Refrigerant leak detectors should be calibrated regularly to ensure accurate readings. Consult the manufacturer’s guidelines for calibration instructions.

Conclusion

Future developments in refrigerant leak detection are centered around advancements in leak detection technology, emerging trends in sustainable refrigerant leak detection, and the potential integration of IoT and smart technologies. These advancements aim to improve the sensitivity, accuracy, and sustainability of leak detection methods, ultimately leading to more efficient and environmentally friendly refrigeration systems.

With a wide range of refrigerant leak detectors available in the market, such as Product A, Product B, and Product C, facility managers have access to highly sensitive and reliable tools for detecting and monitoring refrigerant leaks. It is important to choose a detector that suits the specific requirements of the refrigeration system and ensure regular calibration for accurate readings.